Best Seller

Best Seller

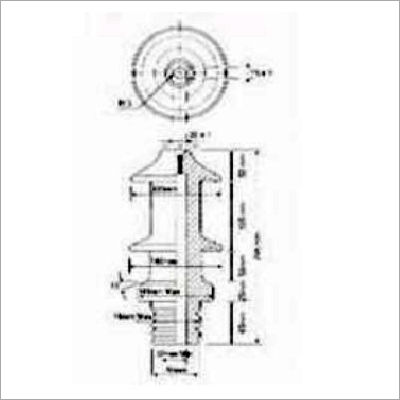

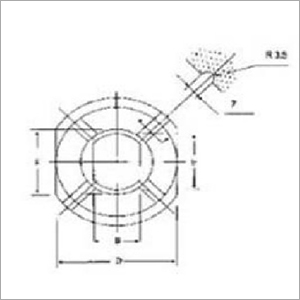

For more efficient usage of electricity...11kV Pin Insulator, 22kV Pin Insulator, 33kV Pin Insulator, Disc Insulator, 11kV and 22kV Post Insulator, 1.1kV Transformer Bushings, 12kV-17.5kV, 24kV, 736kV Transformer Bushings, L.T. Shackle Insulator, L.T. Spool Insulator, L.T.Pin Insulator, etc....

Importance of Insulation

Almost every major facet of a modern home and business, from lights to cooking utensils and from computers to Internet connections, depends upon insulation. Efficient insulation is critical to productive and safe use of electrical energy. There occurs huge loses in the form of leakage during generation and transportation of electricity. As such, rendering standard insulation solutions which enable efficient transportation and generation of electricity is highly beneficial for the electrical industry and in turn for the consumers.

About Us

Satraj Ceramics

provides global industries with a variety of electrical insulation

solutions. With 25 years in business, we have become synonymous with

precision engineered high-tension insulators that possess excellent

dielectric, thermal, corrosion resistance, anti-abrasion and structural

properties. We are a leading manufacturer of Ceramic

Insulators, Porcelain Insulators, 11kV Pin Insulator, 22kV Pin

Insulator, 33kV Pin Insulator, Disc Insulator, 11kV and 22kV Post,

Insulator, 1.1kV Transformer Bushings, 12kV-17.5kV, 24kV, 736kV

Transformer Bushings, L.T. Shackle Insulator, L.T. Spool Insulator, L.T.

Pin Insulator, etc.

Each product, prior to delivery,

goes through rigorous process planning. This allows for the most cost

and time efficient manner of production, with the savings passed on to

our consumers. Apart from generating and pursuing new business

opportunities, we always maintain close relationships with our customers

by continuing to supply them with the highest quality electrical

insulating products.

Satraj Ceramics is driven by a robust infrastructural facility. The efficiency of our manufacturing process helps us to ensure not only bulk production, but also on time completion of the given consignments. We have complete testing facilities to test and check all the major raw-materials used in the production process. Fabrication section cross examines the strength, quality, overall built and fine finish of the products. We are further backed by a qualified team of electrical engineers to carry out all our production activities with ease and finesse.